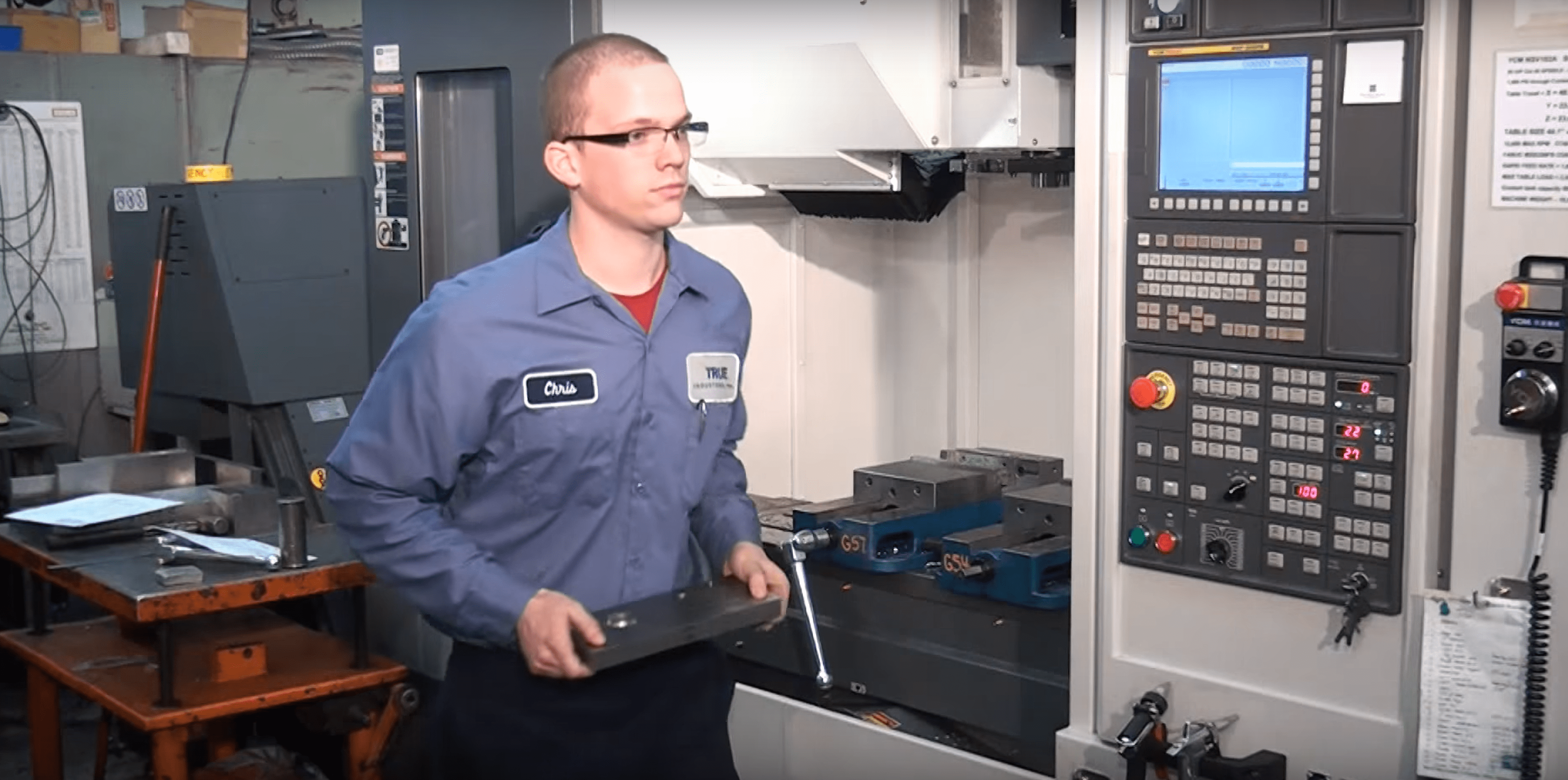

Machining

TRUE Machining & Precision

- Skilled machinists (15 years avg. experience)

- Dimensional accuracy of +/- 0.0005″

- In-house supported CNC programming staff

- Integrated CAD/CAM software for accuracy at every workstation

- Experience with all tool steels (D2, S7, 4140/50, etc.)

- Precision hard cutting capability, no cutter deflection

- CAD retention for all jobs completed (up to 10 years)

5-Axis CNC

Capable of handling complex workpieces

Added August of 2023, this unlimited table weight 5-axis Promac Sharav GVT 3.5 upgraded True’s ability to meet customers needs for aerospace solutions.

| Working Area | X=78″ Y=118″ Z=57″ |

| RPM Range | 50 – 15,000 rpm |

| Cutter Max | Max Dia: 3.93″ (17.6 lbs) |

| Surface Finish | 0.4 Mircons |

CNC Machining

Need precision tooling or detailing?

Our mid to large range precision CNC centers are available to take on the work. TRUE features six total of the following machines…

| NSV102A | X=40″ Y=23.6″ Z=23.6″ |

| DCV2012B | X=78.7″ Y=47.2″ Z=30″ |

| DCV3012B | X=120.5″ Y=63″ Z=30″ |

| OKK VM900 | X=81.1″ Y=37″ Z=32.3″ |

Large Milling

Capable of machining the largest Tool & Die molds.

Our large mill/boring machines support our build and customer repair processes. TRUE features three of the following machines…

| Toshiba BP.110.P20 | X=99.5″ Y=64.5″ Z=45″ W=20″ |

| Toshiba BP.130.P40 | X=160″ Y=94″ Z=60″ W=28″ |

| FPT Synthesis | X=236″ Y=118″ Z=50″ |